Waterproofing Florida's Frost Museum of Science

FRIDAY, APRIL 20, 2018

Case Study By: Brian McGuire, Kemper System America Inc.

The $305 million Phillip and Patricia Frost Museum of Science at Miami’s Museum Park features an open-air atrium and, among other wonders, a 550,000-gallon aquarium that stretches three floors with a 31-foot-wide oculus offering bottom-up views of sharks, rays and other sea creatures.

The 250,000-square-foot museum incorporates numerous sustainable design elements including a “green roof” that is a natural learning environment designed with children in mind.

The exhibits in the aquarium invite guests to learn about the Florida environment and include aquatic and terrestrial habitats with plants, animals and reptiles from the Everglades, hardwood hammocks, coral reefs, the Gulf Stream and more. The green roof, consisting of two rooftop terraces on the museum’s north and west wings, filters rainwater and temporarily retains it, which eases runoff during storms. Roof rainwater is collected, stored and reused as make-up water for the HVAC-system.

|

| Photos courtesy of Frost Science unless otherwise noted |

|

The $305 million Phillip and Patricia Frost Museum of Science at Miami’s Museum Park features an open-air atrium and, among other wonders, a 550,000-gallon aquarium that stretches three floors with a 31-foot-wide oculus offering bottom-up views of sharks, rays and other sea creatures. |

Frost Science is pursuing LEED Gold certification, and will make data from the building’s sustainability initiatives available to visitors and others involved in creating a better future for the planet.

The overall design for the majestic showpiece was developed by Grimshaw Architects (New York, New York), a firm that specializes in high-tech architecture. Rodriguez and Quiroga Architects Chartered (Coral Gables, Florida), which has produced award-winning designs across south Florida, served as architect of record and executive architect. The architectural firms worked together on the project and were supported by numerous project consultants and teams, including one for the design of the life-support system for the Gulf Stream Aquarium.

Strong architectural design arises from and responds to location, so protection from Mother Nature was a prime consideration from the beginning. More hurricanes hit Florida than any other state in the U.S., and in this case, the museum complex is in a flood zone that fronts the Biscayne Bay. With this in mind, the museum was designed to withstand hurricane forces—from the ground level to the roof—as well as flooding from storm surges.

“Water played a vital role in the design of the sustainable building as it is ever-present in south Florida,” said Project Architect Christian Hoenigschmid, of Grimshaw. “The building collects and reuses as much rainwater as possible, while the rest percolates into the ground and charges the aquifer. Salt water is pumped from the Biscayne Bay to the museum for use in the aquarium exhibit with its range of aquatic habitats. This avoids the need for the facility to manufacture seawater, which would normally use vast amounts of potable water.”

FROM THE GROUND UP

Not surprisingly, there are no occupied spaces at ground level. Instead, there is a parking garage plus loading docks, elevator pits and utilities.

“We call this level the ‘bathtub’ but the walls here are designed to keep water out,” says Project Architect Chris Goertz, of Rodriguez and Quiroga. “The ground floor is cast-in-place concrete for all the walls and enclosed spaces, and the concrete surfaces are all flood-proofed up to the plaza level, about 12 feet above the base elevation.”

|

|

The green roof, consisting of two rooftop terraces on the museum’s north and west wings, filters rainwater and temporarily retains it, which eases runoff during storms. Roof rainwater is collected, stored and reused as make-up water for the HVAC-system. |

The expansive Knight Plaza above the parking garage is peppered with planters and connects Frost Science with the Pérez Art Museum Miami, which opened in 2013 and is part of the four-acre Museum Park campus.

“There is flood-proofing, flood barriers and shields in front of all the ground floor openings. It’s a multi-pronged approach with a waterproofing membrane, a crystalline waterproofing integral to the concrete and then the barriers,” Goertz said.

He notes that crystalline waterproofing is different than hydrostatic concrete, which works primarily by repelling water from the surface.

“When water hits the crystal in the admixture, there is a reaction and the gaps in the material close, making the cured concrete far less permeable,” he said.

GREEN ROOF CHALLENGE

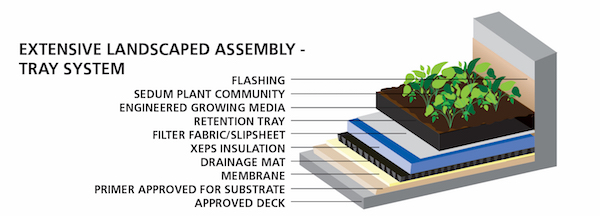

The project uses several different types of roofing systems, including white roofs. However, green roofs pose a special waterproofing challenge because they are not visible. Typically, they include penetrations for drains, pipes or support anchors for utilities such as railings. Active plants can also push against waterproofing materials, especially mature shrubs or trees used for “intensive” green roofs, with beds typically six inches deep or more. The shallower, “extensive” green roof areas of the museum are planted with an array of sedums and small plants selected for the tropical climate.

To address the waterproofing challenges, Rodriguez and Quiroga selected a cold liquid-applied reinforced membrane system from Kemper System America Inc. (West Seneca, New York). Kemperol BRM is a two-component polyester resin membrane reinforced for durability. With an inhibitor, the liquid resin can be applied even in temperatures above 90 degrees Fahrenheit. It fully adheres to surfaces and completely hardens in three days. The finished membrane provides a seamless surface that can withstand ponding water and is both rot- and root-resistant. The membrane is fully reinforced and rated for puncture resistance to 150 lbf (per FTMS 101-2031).

|

| Kemper System America Inc. |

|

The project uses several different types of roofing systems, including white roofs. However, green roofs pose a special waterproofing challenge because they are not visible. Typically, they include penetrations for drains, pipes or support anchors for utilities such as railings. |

Installed by Best Roofing (Fort Lauderdale, Florida), the membrane system is also self-flashing so there is no need for mechanical fasteners or termination bars. The liquid is applied with a roller, a sheet of polyester fleece reinforcement is rolled into the wet resin and another layer of the waterproofing resin is applied to saturate the fleece. Once cured, the result is a monolithic surface.

The reinforced membrane system is pre-applied around drains and penetrations before applying to the field, so areas that might be a prime source of leaks are doubly protected. Unlike board or sheet products, the liquid-applied system easily conforms to any shape, so it could be adapted to the details of the project. The membrane was applied across the floor of the areas to be planted as well as under the walkways and up and over the curbs. It also protects around the stainless-steel drain channel that feeds some planters below.

Goertz explained the assembly for the vegetative areas: “There is a concrete structural deck, then the insulation, then the waterproofing membrane system. On top of that is the green roof, the drainage layer, the filter fabric, the soil and the plant material.”

The same waterproofing system was used for the walkways, though the assembly is different because there is no growing media and the walkways require a slight slope for drainage.

“You use tapered insulation, a fiberglass mat-faced gypsum board, then the membrane system and then pour the slab on top of that.” The tapered insulation provides slope to drain.

Although applying the waterproofing membrane directly to the concrete structural deck would have an advantage for wind uplift, the Florida building code requires a minimum of 3/4-inch-per-foot slope-to-drain for a membrane, Goertz said.

|

| Photo by Ra-Haus, courtesy of Frost Science |

|

The exhibits in the aquarium invite guests to learn about the Florida environment and include aquatic and terrestrial habitats with plants, animals and reptiles from the Everglades, hardwood hammocks, coral reefs, the Gulf Stream and more. |

“If you look at the geometry of the building, it was easier to achieve this with a straight slab and tapered insulation, and that was cheaper and more effective than a sloped deck.” He also noted that the system carries the Miami-Dade product control Note of Acceptance for negative pressure testing.

Goertz points out that different waterproofing assemblies and materials were specified to address specific needs of the project.

“With the open-air design, there are outdoor terraces on every level, and those are spilt slab, topping slab, with the waterproofing in between. So you have a concrete slab, and then the waterproofing, which is sloped with a drainage mat, and a topping slab on top,” he said. “Above the exterior exhibit space with the various open-air aquaria there is a concrete canopy, a thin concrete slab protected by a liquid-applied waterproofing traffic deck. The planetarium is also a pre-cast concrete with exterior waterproofing.”

PROJECT SUMMARY

- Overall project cost: $305M

- Museum opened: May 2017

- Design Architect: Grimshaw Architects

- Architect of Record: Rodriguez and Quiroga Architects Chartered

- Executive Architect: Rodriguez and Quiroga Architects Chartered

- Construction Management: Skanska USA

- Landscape Architect: ArquitectonicaGEO

- Waterproofing Installer: Best Roofing

- Reinforced Membrane System: Kemper System America Inc.

ABOUT THE AUTHOR

Brian McGuire brings over 25 years of experience in the construction industry to his role as Southeast Regional Manager of Kemper System America Inc. He is responsible for business development with architects, engineers and building envelope consultants. McGuire is an active member of RCI.

Tagged categories: Building Envelope; Green roofs; Kemper; Waterproofing; Waterproofing membranes