UTA Professor Develops Drainage-Pipe Polymer

TUESDAY, JANUARY 16, 2018

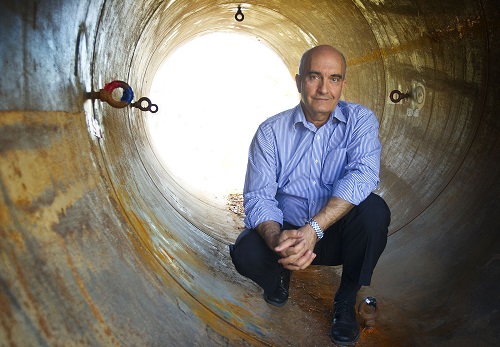

Mohammad Najafi, professor in the Department of Civil Engineering at the University of Texas at Arlington, has received $400,000 in funding to research methods for the application of a lining for storm-water pipes that may increase their longevity.

Pipeline Coating Research

The lining itself is a sprayed polymer or cement-like material.

“We will be looking at how this spray-applied pipe liner affects water-carrying capability and structure capacity in these storm-drainage pipes and culverts,” said Najafi, who is also the director for the UTA’s Center for Underground Infrastructure Research and Education.

|

| University of Texas at Arlington |

|

Mohammad Najafi, professor in the Department of Civil Engineering at the University of Texas at Arlington, has received $400,000 in funding to research methods for the application of a lining for storm-water pipes that may increase their longevity. |

According to the university, Najafi’s research will guide future pipeline decisions for the six departments of transportation that provided funding for the project.

Slip-Lining Limitations

Najafi noted that previously a slip-lining pipe may have been inserted into a deteriorating pipe, but this would have had a negative impact on hydraulic capacity. Similarly, other trenchless technology methods, such as cured-in-place-pipe, might also reduce capacity and not be applicable for hard-to-access locations and larger pipe diameters.

“Those other technologies took up too much room in existing pipes and that reduced how much runoff water could be carried away,” Najafi said. “The new polymer is much, much thinner and much, much stronger.”

The professor added that the water-carrying capacity wasn’t negatively impacted, noting it was imperative that repairs for these pipelines remain cost-effective.

“They want to make sure they’re making the right decisions because these decisions hopefully will allow them to extend the life of the deteriorated drainage structures another 50 years.”

The project is being spearheaded by the Ohio Department of Transportation, as well as DOTs from New York, Florida, North Carolina, Minnesota and Pennsylvania. The grant came from the National Cooperative Highway Research Program, which serves as a hub for collaborative research, and was administered by the Transportation Research Board, in cooperation with the Federal Highway Administration.

Tagged categories: Coating Materials; Coating Materials; Coatings Technology; Colleges and Universities; Pipelines; Polymers; Research