TUESDAY, APRIL 2, 2024

Researchers at the U.S. Department of Energy’s SLAC National Accelerator Laboratory at Stanford University in California have reportedly begun looking into tungsten’s ability to conduct heat for nuclear fusion reactors and other clean energy technology.

According to the team, recent advancements in this research have presented opportunities to help speed up the development of more efficient and resilient fusion reactor materials, as well as aerospace equipment like rocket engine nozzles and turbine blade coatings.

About the Research

Researchers stated that nuclear fusion has been a promising frontier, though things can get too hot when using fusion reactors, where scientists attempt to make energy by fusing atoms together and mimic the sun's power generation process.

To combat this issue, researchers have been looking into heat management, focusing on the special metal called tungsten. The new research reportedly highlights the metal’s potential to improve fusion reactor technology based on this ability to conduct heat.

"What excites us is the potential of our findings to influence the design of artificial materials for fusion and other energy applications," said collaborator Siegfried Glenzer, director of the High Energy Density Division at SLAC.

“Our work demonstrates the capability to probe materials at the atomic scale, providing valuable data for further research and development."

|

| Stanford University |

|

Researchers at the U.S. Department of Energy’s SLAC National Accelerator Laboratory at Stanford University in California have reportedly begun looking into tungsten’s ability to conduct heat for nuclear fusion reactors and other clean energy technology. |

Tungsten is reportedly very strong, can handle incredibly high temperatures and doesn't get warped or weakened by heat waves as much as other metals. Because of these qualities, researchers believe that it could be useful in conducting heat away quickly and efficiently, exactly what's needed in the super-hot conditions of a fusion reactor.

Understanding how tungsten works with heat could potentially offer insight on how to make new materials for fusion reactors even better at keeping cool under pressure. In the new research, the scientists developed a new way to closely study how tungsten manages heat at the atomic level.

The research team reportedly aims to explore the idea of phonon scattering—a process where lattice vibrations within a solid material interact, playing a large role in the material's ability to conduct heat.

Typically, the contribution of phonons to thermal transport in metals was underestimated, with higher emphasis on the role of electrons. However, through a combination of modeling and experimental techniques, the research team shed light on the behavior of phonons in tungsten.

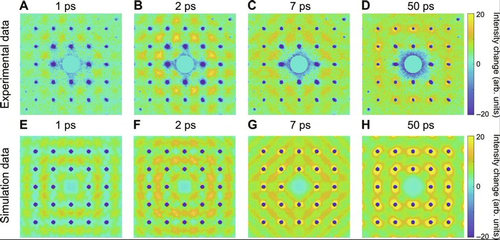

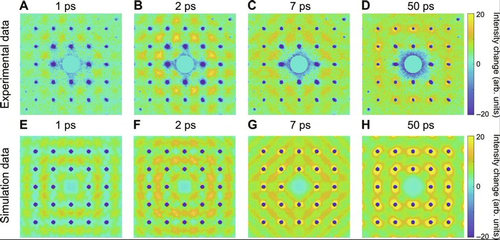

With SLAC's high-speed “electron camera” MeV-UED, the researchers studied the material using a technique called ultrafast electron diffuse scattering (UEDS), allowing them to observe and measure the interactions between electrons and phonons with precision.

This method involved shooting a laser to excite the electrons in tungsten and then observe how these excited electrons interacted with the phonons. The UEDS technique captured the scattering of electrons off phonons, letting researchers watch these interactions in real time.

Additionally, the UEDS helped the researchers differentiate between the contributions of electron-phonon and phonon-phonon scattering to thermal transport, a distinction that is important for understanding the workings of heat management in materials subjected to the conditions of a fusion reactor.

“The challenge lies in distinguishing the contributions of phonons from electrons in thermal transport,” said SLAC scientist Mianzhen Mo, who led the research.

“Our paper introduces a state-of-the-art technique that resolves these contributions, revealing how energy is distributed within the material. This technique allowed us to precisely measure the interactions between electrons and phonons in tungsten, providing us with insights that were previously out of reach.”

The study's results reportedly revealed that in tungsten, the interaction between phonons is much weaker than expected, meaning that tungsten can conduct heat more efficiently than previously thought.

"Our findings are particularly relevant for designing new, more robust materials for fusion reactors," said collaborator Alfredo Correa, a scientist at Lawrence Livermore National Laboratory (LLNL).

“Such precise experiments provide excellent validation for the new simulation technique we employed in this work to describe heat tranport and the microscopic motions of atoms and electrons, allowing us to predict how materials will behave under extreme environments.”

Moving Forward

To follow up on this research, the team plans to investigate the impact of impurities, such as helium, on tungsten's ability to handle heat. Helium accumulation, a product of fusion neutron-induced transmutation in materials, can reportedly affect the material's performance and longevity.

"The next phase of our research will explore how helium and other impurities impact tungsten's ability to conduct heat," Mo said. “This is crucial for improving the lifespan and efficiency of fusion reactor materials.”

Understanding these interactions is reportedly an important step in validating fundamental modelling and developing materials that can withstand the demands of a fusion reactor over time.

This could potentially lead to better materials for fusion reactors, as well as in other fields where managing heat is critical, from aerospace to the automotive industry to electronics.

"This research is not just about improving materials for fusion reactors; it's about leveraging our understanding of phonon dynamics to revolutionize how we manage heat in a wide range of applications," Glenzer said.

"We're not just enhancing our understanding of how materials behave under extreme conditions; we're laying the groundwork for a future where clean, sustainable fusion energy could be a reality.”

The team’s research was reportedly published in the journal Science Advances.

Other Nuclear Research News

In August of last year, the DOE reportedly awarded $7.5 million to engineering researchers at the University of Michigan for research into how reactors can withstand the effects of radiation, corrosion and other stressors. The funding was reportedly meant for several projects as a part of the DOE’s Integrated Research Projects program.

According to the release, the project that received the most amount of funding at $3 million aims to speed up the advanced nuclear reactor licensing process by building a tool that gives companies the data needed for design approval.

The release stated that the Nuclear Regulatory Commission reportedly required extensive data about how new reactors would operate over time, up to 20 years. Companies reportedly need to showed that the parts of the reactor can survive radiation and other stressors. However, at the time, reactors were reportedly slow, expensive and not very available.

As an alternative solution to this issue, the U-M team stated that they will shoot atomic nuclei at the material to create a predictive tool for advanced reactor companies to use so they can show how well their core materials can withstand “decades’ worth of radiation damage.”

The release stated that an additional $500,000 from NEUP was given to a project that will help nuclear scientists and technologists “prepare for the quantum revolution,” stating that algorithms that work on current computers reportedly will not work on quantum computers.

While others were reportedly already at work on how to stimulate fluids with quantum computers, neutrons—particles that trigger fission in nuclear reactors—need attention. A team led by Brian Kiedrowski, associate professor of nuclear engineering and radiological sciences, was planning to begin to encode the behaviors of neutrons in a format that quantum computers can understand.

Additionally, in January of this year, researchers at the GI Budker Institute of Nuclear Physics at the Siberian Branch of the Russian Academy of Sciences reportedly began testing a new coating for the walls of the International Experimental Thermonuclear Reactor (ITER), currently under construction in France.

According to a report from Nuclear Engineering International, the team was looking for a substance to withstand damage caused by plasma burning during a thermonuclear reaction.

The plasma in the tokamak—a machine in the reactor which contains plasma with magnetic fields in a donut shape called a torus—is in a toroidal vacuum chamber. Though it has little contact with the walls due to the retention of the magnetic field, the load on them is still reportedly large.

This is reportedly both heating and radiation flux coming from plasma, or neutron and gamma radiation. The material of the wall in conditions like this can reportedly be destroyed and the wall cover particles should fall into the plasma, though heavy impurities can be especially dangerous.

Substances in plasma like this reportedly lead to its rapid cooling, and finding material for the first wall that would meet all the requirements is very difficult.

Carbon was reportedly used in research tokamaks to protect the walls, however its use caused issues as it can capture and retain hydrogen isotopes, including radioactive tritium. Now, tungsten and beryllium are used as material for the first wall of the camera in ITER.

Tungsten is refractory and can reportedly withstand high temperatures, but it is heavy and when it enters plasma, it quickly cools it. Additionally, beryllium is very light, meaning when it enters plasma it does not affect its quality. However, the dust from beryllium is toxic to humans and is a strong carcinogen.

Because of this, a team of scientists led by Anatoly Krasilnikov, head of the ITER center (Russia’s national agency for the construction of ITER) began looking into alternative options for covering the wall of the tokamak.

The coating reportedly needed to be heat-resistant and made from a light material with high thermal conductivity and electrical conductivity like some special types of ceramics. Typically, ceramics are an insulator, however there are heat-resistant materials of the ceramic class that reportedly have the proper conductivity.

The researchers applied a coating of special material with a thickness of only tens of microns, then began tests at the BETA installation in INP SB RAS, where the material was subjected to thermonuclear pulse loads.

The report added that surface damage can cause roughness to also change. At the BETA complex, the exact moment erosion begins can be identified with the subsequent loss of matter.

The results from testing at the BETA complex have reportedly shown that the threshold values of loads at which ceramics begin to collapse are similar to tungsten. Tests have suggested that boron carbine can compete with tungsten carbide and beryllium coatings.

Tagged categories: Aerospace; Coating Materials; Colleges and Universities; Energy efficiency; Environmental Controls; Green Infrastructure; hazardous materials; Heat-resistive coatings; Metals; Nuclear Power Plants; Performance testing; Program/Project Management; Raw materials; Research; Research and development; Sustainability