THURSDAY, JUNE 2, 2022

The European Space Agency recently announced that it is studying materials for self-cleaning antimicrobial coatings to protect both astronauts and materials on the International Space Station. The ESA’s Materials’ Physical and Chemistry Section is working in collaboration with the Istituto Italiano di Tecnologia.

The PATINA project, or “Optimization of Photo-catalytic Antibacterial coatings,” was proposed through the ESA’s Open Space Innovation Platform, which seeks novel ideas for space research. According to the release, the project also covers other antimicrobial surface treatments, including super-hydrophobic materials that repel all moisture, electro-static reaction and biocide-releasing materials.

About the Research

A microbial survey of surfaces on the ISS reportedly found dozens of different bacteria and fungi species, including pathogens such as Staphylococcus aureus which can cause skin and respiratory infections as well as food poisoning. Biofilms from theses microbial populations can also tarnish and eat away at metla, glass, plastic and rubber on the spacecraft.

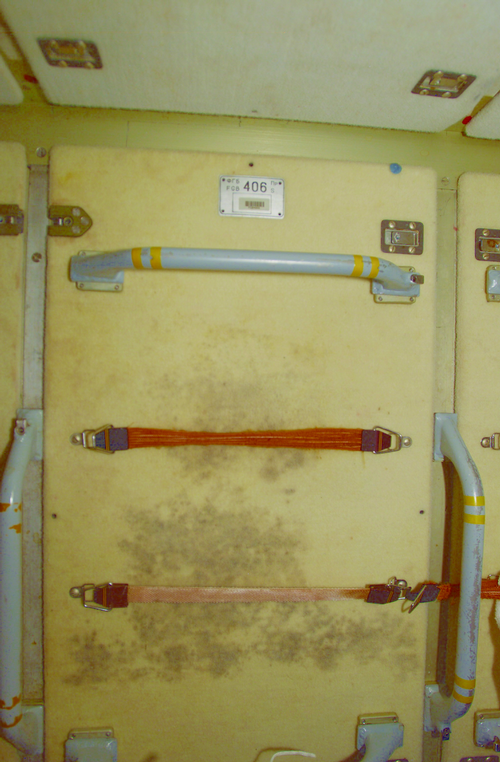

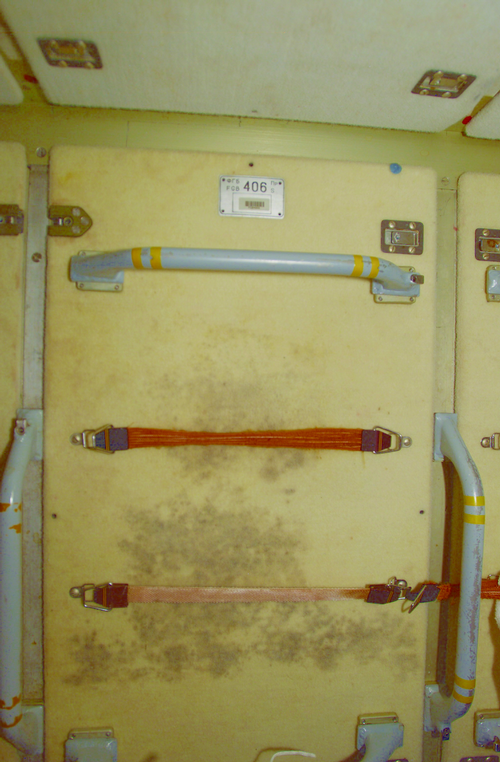

The ISS’s predecessor, the Mir space station, reportedly experienced this issue when microbial colonies were observed growing on spacesuits, cable insulation and the seals of windows.

|

| ESA |

|

The European Space Agency recently announced that it is studying materials for self-cleaning antimicrobial coatings to protect both astronauts and materials on the International Space Station. |

“With astronauts’ immune systems suppressed by microgravity, the microbial populations of future long-duration space missions will need to be controlled rigorously,” explained ESA Material Engineer Malgorzata Holynska.

To combat this, the IIT team started working with titanium oxide, or titania, which is used in self-cleaning glass or hygienic surfaces on Earth. When exposed to ultraviolet light, the material breaks down water vapor in the air into “free oxygen radicals” that eat bacterial membranes.

“Bacteria gets inactivated by the oxidative stress generated by these radicals,” said Mirko Prato of IIT. “This is an advantage because all the microorganisms are affected without exception, so there is no chance that we increase bacterial resistance in the same way as some antibacterial materials.”

Titanium oxide has previously been used for antimicrobial coatings in hospitals, but the researchers are looking at methods to change the compound to increase its sensitivity to the visible portion of the light spectrum.

“Antimicrobial coatings on Earth often make use of silver, but we want to do without it here,” added Holynska. “The issue is that in the confined environment of a spacecraft, prolonged exposure to silver could have negative health effects for astronauts – we don’t want a heavy metal buildup in the onboard water, for instance, with soluble silver linked to skin and eye irritation, even changes in skin color at very high doses.”

Fabio Di Fonzo of IIT added that one of the benefits of titanium oxide is its long-term stability.

“But we will be performing artificial ageing of coatings to see how they evolves over time,” he explained. “And part of the project results will be to see what are the photo-degradation products going back into the cabin atmosphere once the bacteria are oxidised – obviously we don’t want end products that are more toxic than the microbes themselves.”

According to the ESA, the coating was successfully tested on glass, silicon wafer, aluminum foil and clean-room grade paper tissue. This testing was completed through a variety of methods, including physical vapor deposition and atomic layer deposition.

“We aim to keep this antimicrobial layer as thin as possible, so as not to alter the mechanical properties of underlying materials too much, not to stop fabrics from bending and so on,” said Prato. “We are targeting thicknesses of 50 to 100 nanometers, millionths of a millimeter.”

The ESA adds that its research complements existing European research such as the French space-surface experiment MATISS and the German Touching Surfaces experiment investigating bacterial growth aboard the ISS.

NASA Antimicrobial Coatings Research

At the beginning of the year, polymer coatings research conducted by the University of Idaho was launched and installed at the International Space Station, with hopes to minimize bacterial transmission. The university was one of five selected through NASA’s Student Payload Opportunity with Citizen Science (SPOCS) nationwide competition.

The coatings were tested on an aluminum alloy used in high-contact areas throughout the ISS, such as handrails and door handles, to test how microgravity affects the efficacy of the polymers known to resist bacteria adhesion on Earth.

The U of I students submitted a proposal for SPOCS funding in October 2020 as part of their research conducted in fall 2020 as a senior capstone project assigned by Associate Professor Matthew Bernards.

As part of the NASA funding, the team was expected to involve K-12 students in their research. According to U of I, the two polymers selected by trail to go to the ISS were led by the students with over two hundred third- through fifth-grade students at J. Russell Elementary School in Moscow, Idaho.

Researchers refined a non-toxic gel solution containing the bacteria-resistant polymers in petri dishes, and then asked the elementary students to get creative when collecting bacteria. Some of the samples came from sinks, floors, windows, lunch tables, keyboards or hand sanitizer bottles.

Then, the students used a nutrient broth to grow the bacteria in the petri dishes over the next 30 days. After monitoring daily changes, the students reported the two polymers they believed were the best candidates, and the research team analyzed their data to verify those results.

The engineering students also had to design a housing to prevent bacteria from growing before it reaches spaces. Bernards said that the team was limited to a 10-by-10-by-15-centimeter container that could weigh no more than 1.5 kilograms, otherwise less than approximately 3.4 pounds.

NASA also limited the amount of electricity, noise and vibrations allowed for the chemistry to work, with the project needing as little involvement as possible from the astronauts aboard the ISS.

To achieve this, the container holds an upper dry space for electronic storage and a lower wet space for bacteria growth and a set of motorized devices to introduce bacteria. When plugged in, the bacteria encapsulated in a small spring-loaded plunger are introduced into the wet chamber to initiate growth

According to U of I, the device also contains control plates with no polymer coating.

The research was installed onboard the ISS by astronaut Kayla Barron and was scheduled to remain undisturbed for 30 days before being returned to the university for final evaluations and report, including microscopy assessment to determine which polymer best resisted bacteria.

Tagged categories: Aerospace; Antibacterial coatings; Coating Materials; Coatings; Coatings technology; Coatings Technology; Health & Safety; Health and safety; Program/Project Management; Research and development; Self-cleaning coatings; Titanium dioxide