Colorful Plant-Based Films Cool Buildings

THURSDAY, MARCH 30, 2023

Scientists from Cambridge University have recently unveiled a new plant-based coating that gets cooler when exposed to sunlight. Available in a variety of textures and iridescent colors, the material reportedly aims to keep buildings, cars and other structures cool without external power.

“To make materials that remain cooler than the air around them during the day, you need something that reflects a lot of solar light and doesn’t absorb it, which would transform energy from the light into heat,” said Silvia Vignolini, Ph.D., the project’s principal investigator.

“There are only a few materials that have this property, and adding color pigments would typically undo their cooling effects.”

The findings were presented at the spring meeting of the American Chemical Society, which was held virtually and in-person from March 26-30.

About the Research

According to the release from ACS, passive daytime radiative cooling (PDRC) is the ability of a surface to emit its own heat into space without it being absorbed by the air or atmosphere. The result is that the surface can become several degrees colder than the air around it without any electrical power.

|

| Qingchen Shen |

|

Scientists from Cambridge University have recently unveiled a new plant-based coating that gets cooler when exposed to sunlight. |

Some paints and films currently in development can achieve PDRC, but most of them are white or have a mirrored finish, said Qingchen Shen, Ph.D. However, he added, a building owner who wanted to use a blue-colored PDRC paint would be out of luck because colored pigments, by definition, absorb specific wavelengths of sunlight and only reflect the colors we see, causing undesirable warming effects in the process.

Like soap bubbles, color can be shown through a prism instead of the use of pigments. The colors then result from the way light interacts with differing thicknesses of the bubble’s film, a phenomenon called structural color.

ACS reports that part of Vignolini’s research focuses on identifying the causes behind different types of structural colors in nature. In one case, her group found that cellulose nanocrystals (CNCs), which are derived from the cellulose found in plants, could be made into iridescent, colorful films without any added pigment.

“I thought wow, this is really amazing, and I never really thought cellulose could do this,” Vignolini said.

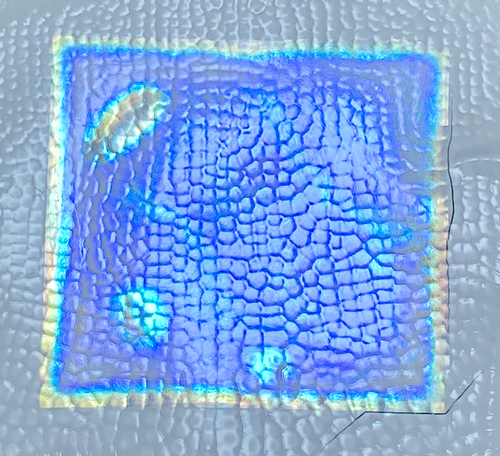

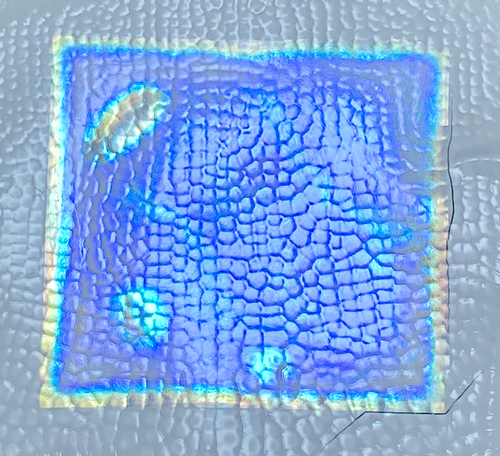

For the research, Shen and Vignolini reportedly layered colorful CNC materials with a white-colored material made from ethyl cellulose, producing a colorful bi-layered PDRC film. They made films with vibrant blue, green and red colors that, when placed under sunlight, were an average of nearly 40 degrees Fahrenheit cooler than the surrounding air.

The researchers said that a square meter of the film generated over 120 watts of cooling power. Since CN films were brittle and the ethyl cellulose layer had to be plasma-treated to get good adhesion, the resulting films are described as robust and can be prepared several meters at a time in a standard manufacturing line.

Afterwards, the team used a method to make the cooling films more aesthetically pleasing with glitter and color. Additionally, they’ve adjusted the ethyl cellulose film to have different textures, like the differences between types of wood finishes used in architecture and interior design, said Shen.

The next steps reportedly include finding ways to make the films more functional. Shen notes that CNC materials can be used as sensors to detect environmental pollutants or weather changes, which could be useful if combined with the cooling power of their CNC-ethyl cellulose films.

The researchers acknowledge support and funding from Purdue University, the American Society of Mechanical Engineers, the European Research Council, the Engineering and Physical Sciences Research Council, the Biotechnology and Biological Sciences Research Council, the European Union and Shanghai Jiao Tong University.

Recent Pigment Alternative Research

Earlier this month, a researcher from the University of Central Florida reportedly drew inspiration from butterflies to create what he says is the first environmentally friendly, multicolor alternative to pigment-based colorants.

According to the university, the research team developed a bio-inspired plasmonic paint, which utilizes nanoscale structural arrangement of colorless materials such as aluminum and aluminum oxide instead of pigments to create colors.

Pigment colorants can control light absorption based on the electronic property of the pigment material, requiring every color to need a new molecule. However, structural colorants control the way light is reflected, scattered or absorbed based purely on the geometrical arrangement of nanostructures.

The researchers reportedly combined their structural color flakes with a commercial binder to form a long-lasting paint in various colors. Additionally, it has been described as the “lightest paint in the world,” due to its large area-to-thickness ratio. Full coloration is reportedly achieved at a paint thickness of only 150 nanometers.

In terms of sustainability, the structural colors use metals and oxides, whereas current pigment-based colors use artificially synthesized molecules. The plasmonic paint also reportedly reflects the entire infrared spectrum, meaning less heat is absorbed by the paint.

The university reports that the surface underneath the paint has stayed 25 to 30 degrees Fahrenheit cooler than it would if it were covered with standard commercial paint. The next steps are expected to further explore the paint’s energy-saving characteristics to improve its viability as commercial paint.

Tagged categories: American Chemical Society; Coating Materials; Coating Materials - Commercial; Coatings; Coatings Technology; Coatings technology; Coatings Technology; Colleges and Universities; Color; Color + Design; Color + Design; Cool Coatings; Energy efficiency; Green coatings; Pigments; Research and development; Texture